Many items in a typical inventory do not actually get repaired and they are simply discarded on failure.

These are known as items with a Discard on Failure Repair Policy.

A customer recently asked:

How should I model with items that have a discard on failure repair policy in Spares Calculator?

Discussion

The short answer to this question is that the repair policy does not affect the calculation. What matters is how long it takes to replace the part. Spares Calculator is based on the Poisson distribution which is used to forecast the projected number of events that might occur when you actually expect something else.

For example, it would be reasonable to expect an item with an MTBF of 1000 hours to fail once in 1000 hours of operation. However, in real life there is actually a 0.05% chance of 5 failures during a 1000 hour operating period.

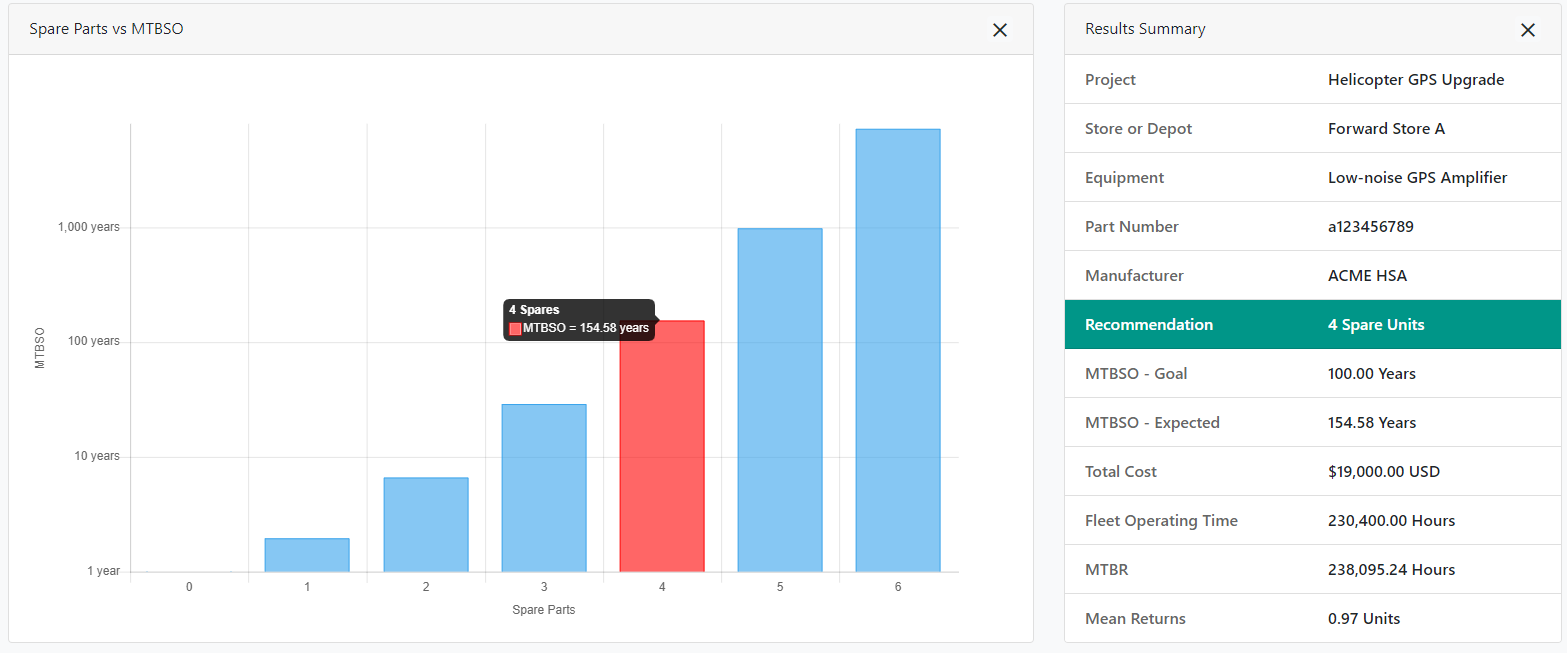

Sample Calculation

A helicopter is equipped with a hermetically sealed low-noise GPS amplifier that has a discard on failure repair policy.

The logistic data is as follows:

LRU: Low-noise GPS Amplifier

Helicopters in Service: 160

LRUs per Helicopter: 2

Daily Operating Hours: 4

Mean Time Between Failures: 250,000

No Fault Found Ratio: 5%

Provisioning Delay: 180 Days (Equivalent to Repair Turn-Around-Time)

Unit Cost: $4,750

MTBSO Goal: > 100 Years

By entering that data in the into Spares Calculator you can see that we would need to procure 4 spare amplifiers at a total cost of $19,000.00 to meet a MTBSO (Mean Time Between Stock-Out) goal of greater than 100 years.